A method for printing a wirelessly chargeable textile energy grid using MXene ink has been created by researchers from Drexel University, the University of Pennsylvania, and Accenture Labs.

Finding a means to charge the clothing devices without having to carry about a bulky battery is the next step towards fully integrated textile-based electronics moving from the lab to the closet.

Researchers from Drexel University, the University of Pennsylvania, and Accenture Labs in California have taken a new approach to the challenge by building a full textile energy grid that can be wirelessly charged.

Researchers from Drexel University, the University of Pennsylvania, and Accenture Labs in California have taken a new approach to the challenge by building a full textile energy grid that can be wirelessly charged. According to the team’s current work, it can power textile devices that communicate data in real-time, such as environmental sensors and warming elements.

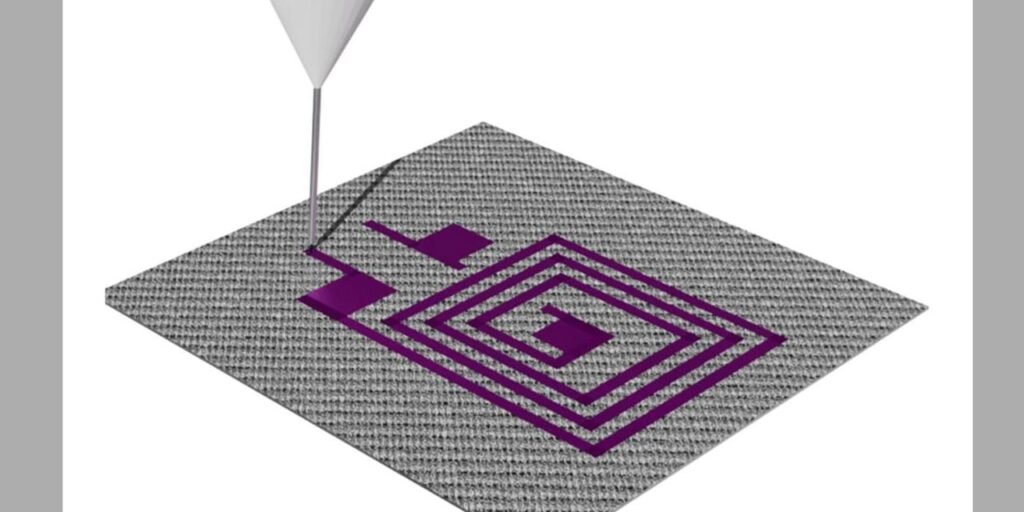

Published in the journal Materials Today, the paper describes the process and viability of building the grid by printing on nonwoven cotton textiles with an ink composed of MXene, a type of nanomaterial created at Drexel, that is at that same time highly conductive and durable enough to withstand the folding, stretching and washing that clothing endures.

Researchers from Drexel University, the University of Pennsylvania, and Accenture Labs in California have taken a new approach to the challenge by building a full textile energy grid that can be wirelessly charged. The proof-of-concept is a significant advancement for wearable technology, which currently has limitations due to the usage of heavy, stiff batteries that are not completely integrated into clothing and necessitates complex cabling.

“These bulky energy supplies typically require rigid components that are not ideal for two main reasons,” said Yury Gogotsi, PhD, distinguished university and Bach professor in Drexel’s College of Engineering, who was a leader of the research. “First, they are uncomfortable and intrusive for the wearer and tend to fail at the interface between the hard electronics and the soft textile over time — an issue that is especially difficult to tackle for e-textiles is the issue of washability.”

By contrast, the team’s proposed textile grid was printed on a lightweight, flexible cotton substrate the size of a small patch. It includes a printed resonator coil, dubbed an MX-coil, that can convert electromagnetic waves into energy — enabling wireless charging; and a series of three textile supercapacitors — previously developed by Drexel and Accenture Labs — that can store energy and use it to power electronic devices.

The grid was able to wirelessly charge at 3.6 volts, which is sufficient to power tiny gadgets like calculators and wristwatches, as well as digital circuitry in computers and wearable sensors. Small gadgets might be powered for almost 90 minutes with just 15 minutes of charge. And after a lengthy series of bending and washing cycles to mimic the wear and tear placed on garments, its performance hardly changed.

Researchers from the University of Pennsylvania, under the direction of associate professor of neurology Flavia Vitale, PhD, showed that the grid can power wireless MXene-based biosensor electrodes, or MXtrodes, that can track muscle movement in addition to testing it with tiny electronic devices.

“Beyond on-garment applications requiring energy storage, we also demonstrated use cases that may not require energy storage,” said Alex Inman, PhD, who helped to perform this research during his internship at Accenture Labs, while a doctoral student and research assistant with Gogotsi in the A.J. Drexel Nanomaterials Institute. “Situations with relatively sedentary users — an infant in a crib, or a patient in a hospital bed — would allow direct power applications, such as continuously wireless powered monitoring of movement and vital signs.”

Similarly, they utilised the system to power a microcontroller to disseminate the data they gathered in real-time, as well as an off-the-shelf array of temperature and humidity sensors. The sensors’ rather energy-intensive real-time broadcasting feature ran for 13 minutes on a 30-minute wireless charge.

Last but not least, as a proof-of-concept, the researchers employed the MX-coil to power a printed, on-textile heating element known as a Joule heater, which generated a temperature increase of around 4 degrees Celsius.

Wireless charging has the potential to power a wide range of technology. According to Gogotsi, the most important factor to take into account when choosing an application is that it must make sense for a wearable device. Since biological sensors are the way of the future for healthcare, we often view them as an extremely alluring application. They may be incorporated straight into fabrics, improving user comfort and data quality and accuracy. However, our research demonstrates that a textile-based power grid could power a wide range of peripheral devices, such as wearable haptics for AR/VR applications like job training and entertainment, fiber-based LEDs for fashion or job safety, and external electronics control when a stand-alone controller might not be desirable.

The next step for developing this technology involves showing how the system could be scaled up without diminishing its performance or limiting its ability to be integrated into textiles. Gogotsi and Inman anticipate MXene materials holding the key to translating a variety of technology into textile form. Not only can MXene ink be applied to most common textile substrate, but a number of MXene-based devices have also been demonstrated as proofs-of-concept.

According to Inman, “the next steps come down to integration because we are producing enough power from the wireless charging to power a lot of different applications.” The fact that MXene may be utilised for a variety of different functions, such as conductive traces, antennas, and sensors, and that material mismatches won’t result in mechanical or electrical failure, is one significant way it can assist with this.

Accenture, LLP and the National Institutes of Health provided funding for the study.

Gogotsi and Inman were joined in this study by Raghav Garg and Flavia Vitale from the University of Pennsylvania; Jung Wook Park, Noah Pacik-Nelson, Eric M. Gallo, and Andreea Danielescu from Accenture Labs; and Bita Soltan Mohammadlou, Kateryna Shevchuk, James FitzPatrick, and Iryna Roslyk from Drexel.