PRISMA is the most recent evidence of Loepfe’s years of leadership in polypropylene clearing innovation. Given that PRISMA is a dynamic system, Loepfe is pleased to report a further advancement in P-clearing. Designed for spinning mills facing fluctuating humidity levels, the system is proven to offer better fabric quality while maintaining the cut rate.

Numerous tests have been carried out over the last 12 months, and a vast amount of data has been gathered and utilised to improve the accuracy of polypropylene identification. The information was utilised for signal processing optimisation and to provide an extra setting function designed especially for spinning mills that had to deal with significant weather variations.

Clearing of polypropylene

For spinning mills, the contamination of cotton with synthetic fibres is still a major problem. Throughout the production process, polypropylene contamination—which usually results from bale packaging—can cause a variety of problems. These include broken needles in knitting applications, thread breakage during weaving, and visible defects in the final product after dyeing. Effective contamination clearing substantially enhances yarn quality, while overly stringent measures can negatively impact production efficiency and increase waste.

Ingenious P-clearing helps spinners strike a compromise between maintaining operational efficiency and the demand for high-quality yarn. Loepfe’s method, which has been improved to explicitly account for humidity swings, addresses a variety of manufacturing circumstances by combining cutting-edge technology, accurate signal processing, and customised settings.

A new form of climate compensation

PRISMA now has a novel climate compensation setting to address the particular requirements of spinning mills that operate in settings with large humidity fluctuations. Numerous advantages have been shown by extensive testing of this new capability at the impacted spinning mills, including:

- Improved overall accuracy of categorisation

- Better performance in clearing

- Reliable cut rates combined with excellent finished fabric quality

- Better clearing performance with the same cuts

In a spinning machine, the new feature makes it simple to combat climate change. The algorithm then computes an average value between the standard deviation and the peak values while accounting for the rising humidity.

Loepfe enables spinning mills to maintain optimal performance and outstanding quality even in the face of harsh environmental circumstances by offering this improved climate adjustment option.

P-Clearing Matrix

The P-Matrix allows operators to input specific parameters, starting with a pre-generated clearing curve by the Autostart function that considers the most crucial factors for optimal and efficient clearing results. By easily adjusting the settings – raising or lowering the clearing curve – operators can tailor outcomes to meet their individual production needs.

The following are the main factors influencing polypropylene clearing:

- Raw material (content of short and long fibres)

- Count of yarns

- The amount of twist in the yarn

- Hairiness of the yarn

- The effect of humidity on hairiness

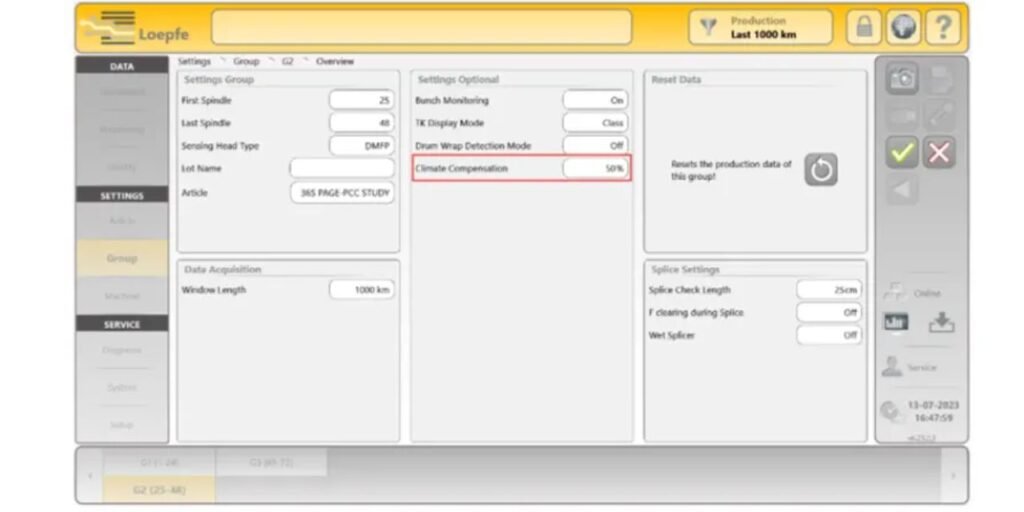

Setting up P climate compensation

Select 50% Climate Compensation under Default Group Settings. To make it visible in Group Settings, tick the Adjustable in Group box. By default, this 50% will be applied to every group. The Default Group Setting cannot be accessed without the service key.

The number of yarns and cotton type may have an impact on the Climate Compensation value. Since several experiments indicate that the greatest results may be obtained between 35% and 75%, it is advised to begin with a value of 50%.