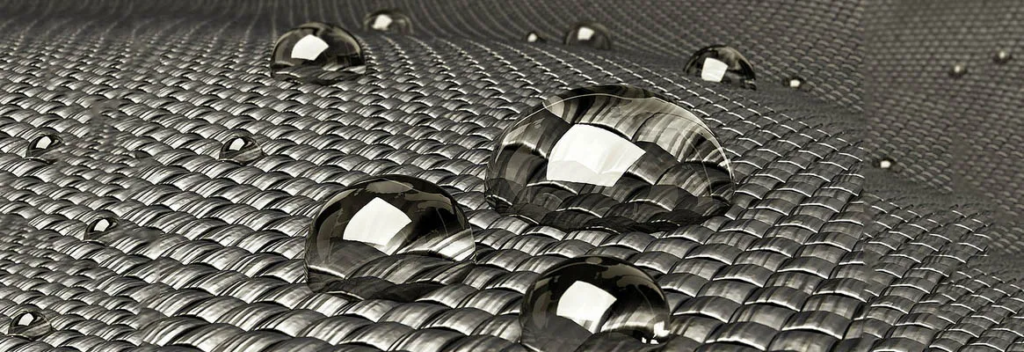

Textile materials have intrinsic properties that make them very valuable, flexible, lightweight, strong, large surface to volume ratio, good touch, softness, etc. Because of this, they are excellent for imparting additional functionalities like hydrophobic, oleophobic or antibacterial. Traditional wet methods for applying these finishes require the use of large amounts of chemicals, water and energy. Plasma is a dry processing technique and provides a solution to reduce the use of all three mentioned resources. In this overview, a discussion on how plasma can achieve on textile materials and what the current state of integration in textile processing has presented.

Plasma is an ionized form of gas and can be created using a controlled level of AC or DC power and an ionizing gas medium. It is an ensemble of randomly moving, charged atomic particles with a sufficient particle density to remain, on average, electrically neutral. Plasma contains positive ions, electrons, neutral gas atoms or molecules, UV light and excited gas atoms and molecules, which can carry a large amount of internal energy (plasmas glow because light is emitted as these excited neutral particles relax to a lower energy state). All of these species can and do interact with any surface placed in contact with the plasma. By choosing the gas mixture, power, pressure etc. we can quite precisely tune, or specify, the effects of the plasma upon the surface. We are all familiar with solid, liquid and gas the three states of matter & we can move between the states by adding or removing energy (e.g., heating/cooling). If we continue to add enough energy, gas molecules will become ionized (lose one or more electrons)and so carry a net positive charge…..