Emphasis on increased recycled content in product range.

New solutions for automotive interiors, packaging and green roofing will be among products highlighted by Freudenberg at the forthcoming Techtextil exhibition in Frankfurt from April 23-26.

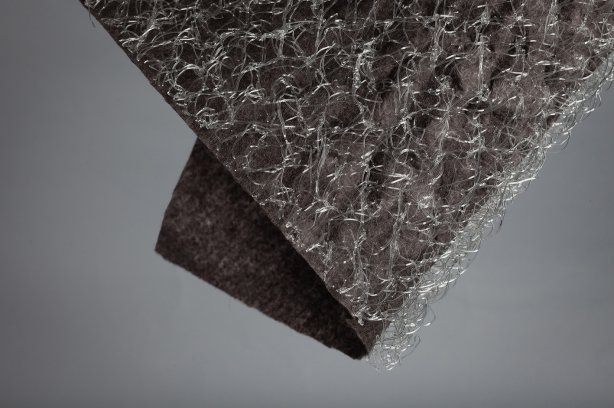

A new soft and flexible polyester nonwoven material for car seat padding, which is also available as a composite with PU foam, is not only easier for car seat manufacturers to handle during the mounting process, but also ensures better dimensional stability. The fully recyclable material has low volatile organic compounds (VOCs) content and a minimum 25% recycled content from industrial waste. Several other nonwoven solutions made of up to 80% recycled materials can be used in car seat manufacturing.

A sustainable carrier material made from PLA for green roofs on urban buildings will also be displayed. When filled with soil, it provides a strong foothold to root systems, enabling the growth of lightweight sedum blankets that can be rolled out to provide instant green roofs. These roofs not only help counter urban heat, but also improve stormwater management and regulate indoor temperatures.

The company is also expanding its circular thermal wadding product range with the release of comfortemp HO 80xR circular made from 70% recycled polyamide derived from discarded fishing nets, carpet flooring and industrial plastic. Polyamide 6 retains its performance characteristics after multiple recycling processes enabling the fibres to be used again and again.

Freudenberg has also contributed thermal insulation to the first parka made from 100% recycled waste clothing enabled by loopamid, the nylon fibre developed by BASF that simplifies the textile-to-textile recycling of nylon garments.