BTMA’s Cutting-Edge Innovations Showcased at Techtextil 2024

Fibre Extrusion Technologies Leading the Way in Advanced Sustainable Fibres and Functional Properties at Techtextil 2024

FET specialises in creating unique fibres for specific uses. They offer fibres made from sustainable materials like recycled plastics and organic sources, alongside those with innovative features for demanding applications. Many will be on display at Techtextil 2024 (Frankfurt, April 23-26).

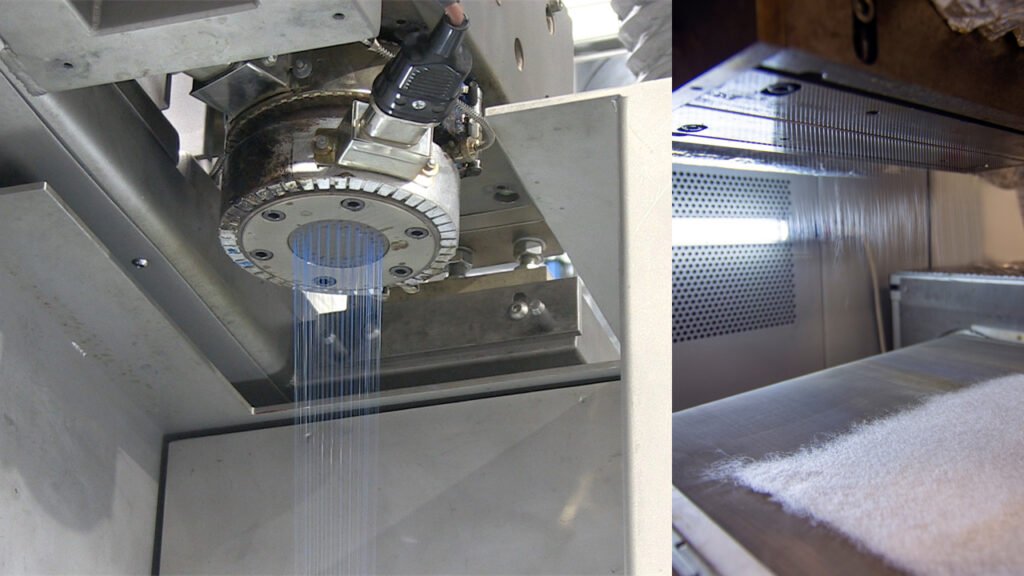

Their expertise lies in developing various fibre types (multifilament, monofilament, nonwoven) for niche applications. They’ve created over 70 so far, and also design custom systems to produce them effectively (extrusion, spunbond, meltblown).

A recent expansion of their development centre significantly boosted their capacity and efficiency. This has allowed them to conduct many more technical trials for clients (start-ups, multinationals, etc.).

“We collaborate with a wide range of clients,” says FET’s managing director. “Currently, biopolymers and recycled fibres are a major focus, as they require special handling due to their unique properties. We excel at processing challenging materials.”

“Medical devices are another area of interest,” he continues, “particularly resorbable products and controlling absorption rates. There’s also a demand for longer-lasting implants for certain surgeries.”

FET is also developing innovative high-performance products. This includes non-traditional hollow fibres made from high-temperature polymers (PEEK) and small-scale nonwovens for filtration applications.

Finally, they’re exploring using olefins to achieve properties similar to UHMWPE. UHMWPE is currently only available in large quantities, but there’s a need for smaller amounts for niche projects. FET believes a specific olefin with a long molecular chain could address 80-90% of this market.

Airbond Introduces Revolutionary Splicing Technology for Efficient Processing of High-Value Fibres

Airbond, a leading innovator in the textile industry, has unveiled cutting-edge splicing technologies at Hall 12, stand E31, aimed at enhancing resource efficiency in handling premium fibres like UHMPWE, carbon, and aramids. The latest pneumatic yarn splicers, featuring patented 3D printed designs, are lighter, stronger, and capable of splicing yarns up to 16,000 tex – a significant advancement compared to conventional machines.

According to Airbond research engineer Carwyn Webb, a deep understanding of splicing physics has enabled the company to revolutionise the splicing process, resulting in stronger and smoother joints while minimising wastage. By pushing the boundaries of traditional splicing machines, Airbond’s technology promises a substantial reduction in costly waste associated with delicate or larger yarns, setting a new standard in textile processing efficiency.

Cutting-Edge Fiber Testing Technologies Unveiled at Techtextil 2024

The upcoming Techtextil 2024 exhibition will feature groundbreaking advancements in the testing of fibres and advanced materials, as leading members of the British Textile Machinery Association (BTMA) are set to showcase their latest innovations. James Heal and Verivide will present their sophisticated systems in Hall 12, stands A40 and A70 respectively, highlighting their extensive collaborations with major producers of technical textiles.

A notable highlight at the event is the introduction of the WebSpector automated fabric inspection system by Shelton Vision at Hall 12, stand E54. This state-of-the-art technology promises precise fault detection during the production of technical fabrics, offering a significant leap forward in quality control. Shelton Vision’s cutting-edge image processing techniques can now identify and adapt to intricate patterns, even on fabrics with notable distortion and deformation, solidifying their position as market leaders in textile vision systems.

BTMA Members to Showcase Latest Innovations at Techtextil 2024

Several prominent members of the British Textile Machinery Association (BTMA) are gearing up to exhibit their cutting-edge products at Techtextil 2024. Avocet, Ascotex, and Vandewiele UK are among the key players set to showcase their latest technologies at the event. Avocet will present its Cetaflam high-performance flame retardant chemicals, while Ascotex will highlight its expertise in yarn guide development. Vandewiele UK, the UK arm of Bonas Textile Machinery, will focus on high-capacity jacquard technology for the weaving industry. BTMA CEO Jason Kent emphasised the importance of innovation in meeting market demands, particularly in sustainability and new technologies. Founded in 1940, BTMA continues to promote British textile machinery manufacturers globally, fostering collaboration with various sectors in the textile manufacturing industry.