Insights Outlast Technologies’

Aersulate is an ultra-thin, high-performance textile insulation made from aerogel, the lightest solid in the world. Its 1-3 mm thickness allows it to maintain its thermal qualities despite dampness and pressure, which makes it perfect for work safety gear, shoes, and apparel. Derived from quartz sand, Aersulate outperforms traditional insulators and supports diverse applications.

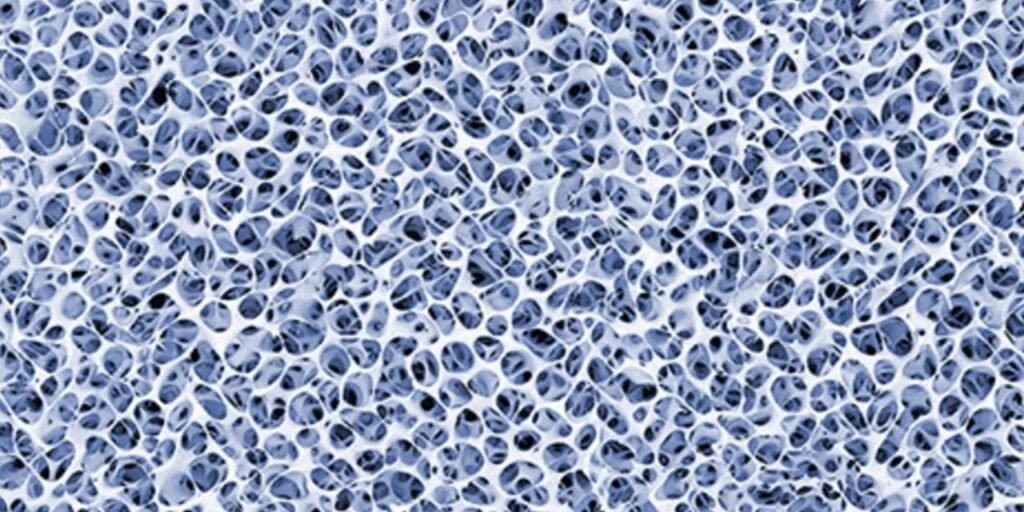

Aerogel is the world’s lightest solid, made composed of up to 99.8% air. That’s not all, though. The substance, which is also known as “frozen smoke” because of its physical characteristics and appearance, has a very low heat conductivity that is far lower than that of other insulations. NASA has been employing aerogel for aeronautical applications for many years because of this. In spite of this, during the material’s approximately 90-year existence, it has not been feasible to bind the substance to textiles in a high concentration and allow for simple further processing—until now. Outlast Technologies GmbH has created a novel method for permanently affixing substantial quantities of aerogel to various media, such as felt, composites, and nonwoven fabric. They may be readily processed further using standard production techniques since their original qualities are maintained throughout. The unique feature here is that the textiles marketed under the Aersulate brand are just 1 to 3 mm thick.

thick and attain extremely high insulation values that are mostly maintained even in damp and pressured environments. They may be utilised for sleeping bags, technical applications, shoes, clothes, and work safety goods, and they remain soft despite their strong performance. Outlast’s method has previously been the subject of a patent application.

“NASA has already been using aerogel for many years because of its extraordinary physical properties,” said Volker Schuster, head of Research and Development at Outlast Technologies. For instance, to shield its Mars rovers and to collect dust from a comet’s tail during the The Stardust mission,” he added. Despite much research, no one has been able to put aerogel, a flexible substance created by American scientist and chemical engineer Samuel Stephens Kistler in 1931, to textiles in significant quantities without altering their original qualities. investigation. This indicates that in addition to frequently being extremely stiff, the goods’ high degree of dust abrasion prevented processing using traditional production techniques. The German textile temperature regulation expert, Aersulate, is currently making insulating history with its recently created Aersulate technology.

High-quality insulation that is only 1 to 3 mm thick

Because of its thinness, Schuster stated, “the consistency of aerogel can be best described as liquid dust particles which spread uncontrollably throughout a room within seconds.” “For this reason, processing is very difficult.” Despite these challenges, Outlast Technologies has successfully developed a novel method that involves attaching aerogel between many layers of material to market maturity after around five years of research. The medium might be nonwoven fabric, felt, or other composite materials, depending on the application. What’s unique in this case is that the Aersulate technology does not negatively impact the qualities of the corresponding textiles, thus even with their acquired thermal properties, they may be readily processed further using traditional methods and in an industrial setting.

Although aerogel is a silicate-based solid made from natural quartz sand, it has a density that is more than 1,000 times lower than that of glass made from the same raw material. The material’s very porous structure, which allows it to contain up to 99.8% air, gives it exceptional thermo-insulating qualities. According to Schuster, “one litre of aerogel weighs just 50 grammes.” “However, a soccer field’s surface area is only 10 grammes of the material.” Despite being only 1 to 3 mm thick, Aersulate textiles outperform all other insulating materials that were previously known in terms of performance because of these characteristics. Aersulate fleece has more than double the thermal resistance of a normal fleece of the same thickness, according to tests conducted by the German Institute for Textile and Fibre Research in Denkendorf (DITF) using the Alambeta technique. Furthermore, under pressure and moisture, the thermo-insulating qualities of Aersulate products maintain their high levels, but those of other traditional materials, such as felt and polyurethane foam (PU), drastically diminish.

Aersulate’s practical apparel and work safety

Thin Aersulate products are particularly appropriate for the shoe and apparel industries, as well as all sectors of work safety, because of the textile medium. Various qualities are advantageous to the user based on the intended application. “For instance, you can submerge your hand in boiling water without getting burned if you have an Aersulate glove that is only 1 mm thick,” Schuster said. “The highly hydrophobic qualities of the material literally work in our favour here.” However, when compression happens, the material qualities also become important in the case of knee patches on work and functional trousers, as well as shoes and soles. This is because perspiration from the inside and moisture from the outside, as well as the ongoing impact of body weight, would gradually diminish the thermo-insulating qualities of other materials.

Aersulate may be used to protect not only the human body but also baggage and electronic items from severe weather conditions and temperatures. In order to prevent the gadgets from overheating in the event of excessive heat exposure and to preserve their battery life even in extremely cold weather, matching pockets for mobile phones or other equipment may be sewed into clothing. According to Schuster, “Aersulate is appropriate for all applications requiring high thermal resistance on the one hand, where only a little space is available and both compression and moisture can be expected on the other,” because of the wide variety of textile medium materials that are accessible.