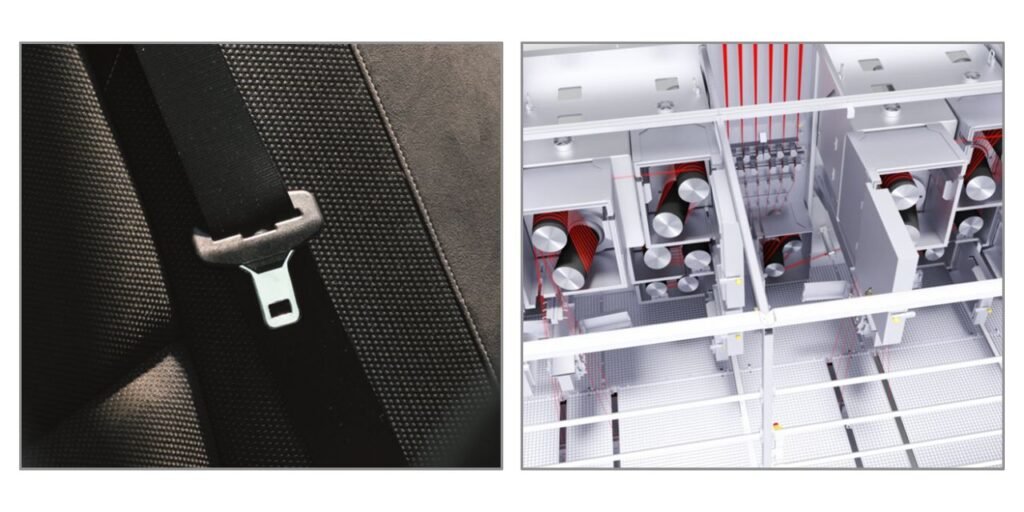

Caption: Oerlikon Barmag supplies its industrial yarn systems individually configured; the system concept for High Tenacity (HT) yarns and its unique properties on the market ensure the production of high-quality yarn for the manufacture of seat belts.

A longtime mainstay of the textile industry, India has cemented its place as the world’s leading producer of man-made fibers in recent decades. The nation is now the second-largest producer of polyester yarn in the world. The domestic textile industry boasts a comprehensive value chain, encompassing the entire production process from raw material to finished product.

A particularly promising segment is technical textiles, a sector characterised by robust growth. Since 2013, it has expanded at an average annual rate of 12%, now constituting approximately 13% of India’s total textile and apparel market, according to Invest India. This dynamic industry has nearly doubled in size over the past decade.

In the past, India has relied mostly on polyamide as the principal fiber for producing industrial yarn; Oerlikon Barmag is a major player in this industry. Oerlikon Business Unit Manmade Fibres Solutions’ Head of Sales, Dr. Wolfgang Ernst, attests to the company’s recent active participation in setting up new manufacturing facilities for several Indian clients.

Intense Demand for Industrial Yarns of Polyester

Significant growth is being driven by the surge in building and the increasing use of industrial textiles and geotextiles in the infrastructure, agricultural, and aquaculture sectors. The government’s 2021 industrial development program, which gives technical textiles top priority among 10 important industries, is another factor driving this rise. Since India has historically depended significantly on imports for technical textiles and yarns, the effort seeks to lessen import reliance.

Oerlikon Barmag has seen an increase in the need for superior technical fabrics in the home market. Dr. Ernst notes that more Indian clients are contacting him in search of industrial yarn spinning devices. The growing interest of downstream processors in investigating backward integration is an interesting trend. The Bureau of Indian Standards’ tougher rules are to blame for this change. Last year, the government imposed strict regulations to guarantee the quality of processed yarns, which led Indian textile manufacturers to start producing yarns. This trend was demonstrated at the most recent Techtextil trade show in Frankfurt, when Oerlikon Barmag had many technical conversations with Indian customers and prospective clients.

The industrial yarn technology from Oerlikon Barmag provides adaptability without sacrificing yarn quality. The company’s adaptable spinning principles can support a wide range of yarn products for different purposes. The portfolio includes production procedures for polyester and polyamide yarns that are customized to meet certain end-use needs. Offering customized solutions, the Remscheid-based solution supplier provides yarns for geotextiles, airbags, safety belts, and automobile tires in addition to HMLS yarns.

About The Division of Oerlikon Polymer Processing Solutions

Oerlikon is a top supplier of precise flow control parts and complete polymer processing plant solutions. The division offers a range of equipment and solutions for textile, injection moulding, and other industries. Its technology brands – Oerlikon Barmag, Oerlikon Neumag, Oerlikon Nonwoven, and Oerlikon HRSflow – serve customers in over 120 countries.

Oerlikon Polymer Processing Solutions Division is part of the Oerlikon Group, a publicly listed company headquartered in Switzerland.