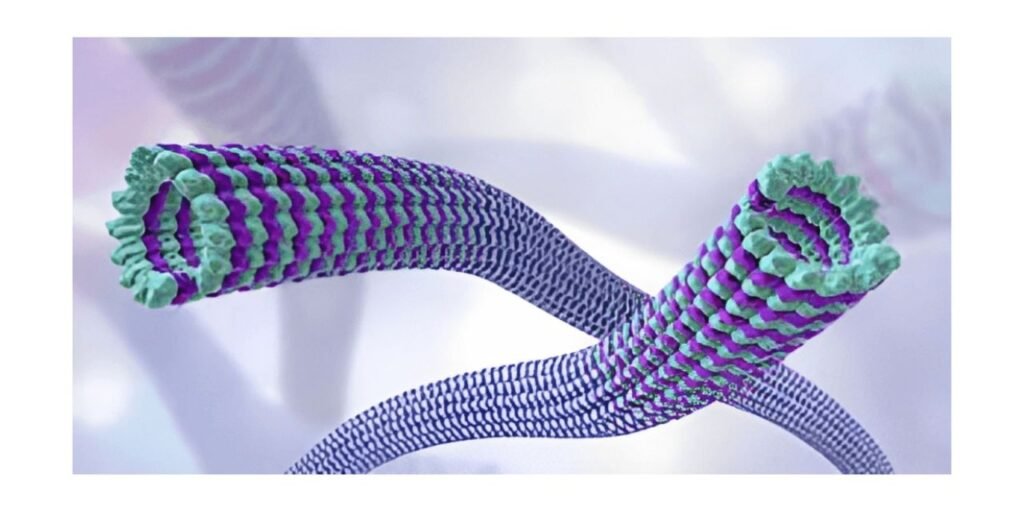

The report “Medical Polymer Market by type (Medical plastics, Medical elastomers), Application (Medical Disposables, Medical Instruments and Devices, Prosthetics, Diagnostics Instruments and Tools), Manufacturing Technology, and Region – Global Forecast to 2029″, is expected to grow at a CAGR of 8.0% during the forecast period, from an estimated USD 41.1 billion in 2024 to USD 60.5 billion by 2029. The growth of the medical polymer market is fueled by several key factors. Technological advancements, especially in areas like 3D printing and nanotechnology, have expanded the possibilities for medical polymer applications. Increasing awareness about infection control and patient safety has led to the development of antimicrobial and biocompatible polymers. Moreover, the trend towards personalized medicine and minimally invasive procedures drives the demand for specialized polymers that offer precise properties. Additionally, environmental concerns are pushing the industry towards bio-based and sustainable polymers, further driving market growth.

Browse

- 341 Market data Tables

- 65 Figures

- 439 Pages and in-depth TOC on “Medical Polymer Market – Global Forecast to 2029”

Some of the prominent key players are:

· BASF SE (Germany)

· SABIC (Saudi Arabia)

· Covestro AG (Germany)

· Celanese Corporation (US)

· Evonik Industries (Germany)

Driver: Increasing demand for biocompatible materials

The increasing demand for biocompatible materials is a pivotal driver propelling the growth of the medical polymer market. Biocompatible materials refer to substances that are compatible with living tissues and organisms without causing adverse reactions such as inflammation or rejection. In the healthcare sector, the demand for biocompatible materials stems from their critical role in medical devices, implants, and drug delivery systems. Patients and healthcare providers alike prioritize materials that seamlessly integrate with the body, minimizing the risk of complications and enhancing treatment outcomes. One of the key factors driving this demand is the rising prevalence of chronic diseases and age-related conditions globally. As the incidence of conditions such as cardiovascular diseases, orthopedic disorders, and diabetes continues to increase, there is a growing need for medical devices and implants made from materials that are not only durable and functional but also compatible with biological systems. Biocompatible polymers such as polyethylene glycol (PEG), polylactic acid (PLA), and polyvinyl alcohol (PVA) have gained traction due to their biodegradability, low toxicity, and ability to mimic natural tissues. Moreover, advancements in material science and polymer engineering have led to the development of innovative biocompatible polymers with tailored properties, including enhanced mechanical strength, controlled degradation rates, and improved biocompatibility profiles. These materials play a crucial role in areas such as tissue engineering, regenerative medicine, and minimally invasive surgeries, driving the adoption of biocompatible polymers across diverse medical applications. As healthcare technologies continue to evolve, the demand for biocompatible materials is expected to remain strong, creating opportunities for market players to innovate and meet the evolving needs of the healthcare industry.

Based on manufacturing technology, injection molding is the fastest growing manufacturing technology in the medical polymer market.

Injection molding stands out as the fastest-growing manufacturing technology in the medical polymer market due to several key factors. Firstly, its ability to produce complex and customized medical components with high precision and efficiency makes it indispensable in the medical device manufacturing sector. This technology enables the mass production of medical products such as syringes, catheters, and implants, meeting the growing demand for these devices globally. Additionally, injection molding offers advantages such as cost-effectiveness, shorter production lead times, and minimal material wastage, making it highly attractive to medical device manufacturers seeking efficient and scalable production solutions. Moreover, ongoing advancements in injection molding processes, including automation and digitalization, continue to enhance its capabilities and contribute to its rapid growth in the medical polymer market.

Asia Pacific is expected to be the fastest-growing market during the forecast period.

The Asia Pacific region emerges as the fastest-growing region in the medical polymer market due to several key factors. Firstly, the region’s rapid economic development and increasing healthcare expenditure are driving the demand for advanced medical devices and equipment, which heavily rely on medical polymers. Moreover, the region benefits from a large and aging population, leading to a higher prevalence of chronic diseases and the need for medical interventions. Additionally, favourable government initiatives, investments in healthcare infrastructure, and a robust manufacturing ecosystem contribute to the region’s growth. Furthermore, the shift towards personalized medicine and the adoption of innovative medical technologies further propels market expansion in the Asia Pacific region, positioning it as a dynamic and lucrative market for medical polymers.

Download PDF for Top Related Reports of Resins and Polymers Industry:

· Post-Consumer Recycled Plastics Market