The Instrumar Fiber System draws on more than 20 years’ experience to utilise unique electromagnetic sensors with a superior ability to detect a wider range of fibre defects.

The global textiles industry is experiencing an era of unprecedented automation, alternatively referred to as the Industrial Internet of Things (IIoT), Industry 4.0, or ‘hyperautomation’ making manufacturing smarter, and more interconnected than ever.

This in turn is placing a renewed emphasis on ensuring quality control throughout the process, not just a checking system applied at the end. A recent report on hyperautomation by Forrester found that 43% of decision-makers ranked autonomous, self-guided and dynamic processes that leverage Artificial Intelligence (AI) as a high priority as part of a drive to increase productivity, agility and speed in manufacturing.

Real-Time Quality Management (RTQM) is an essential part of the automation process, and within this, sophisticated sensors and software are assuming increasing importance because of the link to industrial robotics and AI. In this feature, we look at what RTQM is, its importance now and future potential for textiles – fibre and yarn manufacturing in particular.

The rise of IIoT, the drive to more connected supply chains and demand for transparency mean that traditional forms of quality control are no longer enough. The increasing use of more powerful quality systems by downstream customers is expected to result in increased pressure on upstream fibre producers as their customers are getting better at spotting any quality issues that may have made it through to them.

An example of this already being seen is the use of machine vision systems in circular knitting and weaving. Data, information exchange and quality control need to take place in real time. The alternative leads to delays, spoiled stock, increased waste and environmental impacts, loss of reputation and business.

Advances in the three key technology areas of sensing, data analytics and automation are allowing for manufacturing processes to be monitored continuously in real-time, with quality issues identified and acted on quickly. Instrumar have developed a system tailored to address the specific needs of synthetic fibre production.

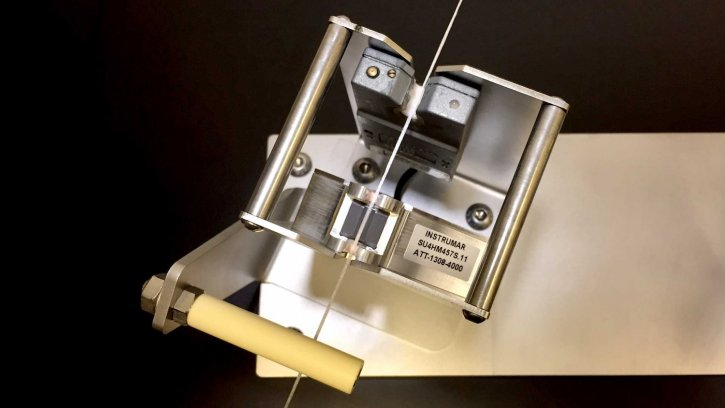

The Instrumar Fiber System draws on more than 20 years’ experience to utilise unique electromagnetic sensors with a superior ability to detect a wider range of fibre defects such as node count and quality that could significantly impact the dye consistency and quality further along the production chain.

The ability to detect multiple issues is important to identify and address problems in a timely and efficient manner. In addition to node count and quality, The Instrumar Fiber System also identifies spin finish fluctuations, variable denier, filament migrations, and fluffs or ‘slubs’. The software can often suggest the underlying causes for these defects, such as operator error or machine issues such as clogged jets, pumps, heater and other problems.

It is this combination, along with the ability to integrate with the machine control systems to automatically take action to downgrade and control production, that marks it as unique amongst quality control approaches available on the market.