Mr. Dhobhi’s Waterless Laundry Revolution: A Rags-to-Riches Story

By. Ram Ramprasad

The story presents a fictional narrative centered on the development and implementation of liquid CO₂ laundry technology in India. While the specific events and characters are fictional, the described benefits and applications of liquid CO₂ cleaning technology to India align with real-world capabilities.

In the bustling streets of Patna, Bihar, Mr. Dhobhi ran a small laundromat—a modest family business passed down through generations. With wrinkled hands and an eye for cleanliness, he had spent decades washing clothes using traditional methods—scrubbing, soaking, and sun-drying.

But times were changing. Water shortages had become severe, and households struggled to secure clean water, often relying on expensive and unreliable tanker deliveries. Labor costs were rising, making it increasingly unaffordable for families to hire help for hand-washing clothes. Witnessing these challenges firsthand, Mr. Dhobhi envisioned a future where laundry didn’t depend on water.

Then, fate took a turn.

A Trip to Chicago That Changed Everything

One day, his nephew, a student in the United States, invited him to visit Chicago. While there, he introduced Mr. Dhobhi to Mr. Thompson, an entrepreneur who ran a laundromat using Tersus Solutions’ liquid CO₂ machines.

Mr. Thompson had secured laundry contracts with a few major hotels and hospItals, leveraging Tersus’ partnerships with industry leaders in fashion, outdoor gear, and industrial laundry services. Among its most notable collaborations was Patagonia, a brand known for its environmental commitment.

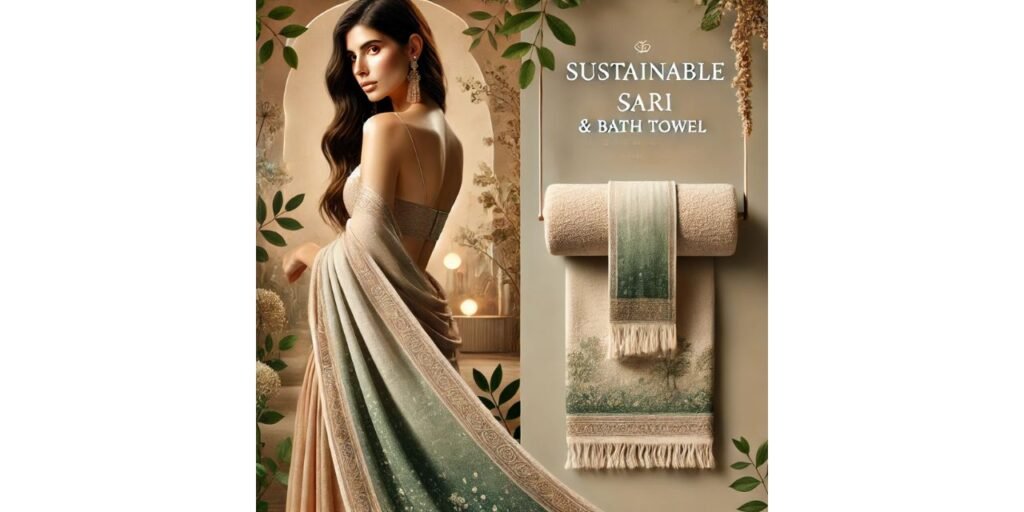

Patagonia, famous for its sustainable clothing line, needed an innovative, eco-friendly solution to clean and refurbish worn garments while maintaining fabric integrity. Traditional washing methods caused wear and tear, leading to faster degradation. Tersus’ liquid CO₂ technology addressed this challenge by using compressed CO₂ instead of water, gently removing dirt, oil, and odors while preserving the fabric’s structure. This partnership allowed Patagonia to extend the lifespan of its garments, aligning with its sustainability goals and reducing textile waste.

Mr. Dhobhi was impressed at what he saw. Instead of traditional water-filled washing drums, sleek, efficient machines used compressed liquid CO₂ to clean clothes.

As Mr. Thompson explained the process, Mr. Dhobhi listened in awe:

1. Liquid CO₂, sourced from industrial byproducts, replaces water.

2. The cleaning cycle is closed-loop, reusing CO₂ with minimal waste.

3. Clothes emerge completely dry, reducing energy costs.

4. Liquid CO₂ is gentle on fabrics, extending garment lifespan significantly.

5. Each batch of liquid CO₂ is used for multiple cleaning cycles.

6. Machines are scalable, with the largest handling over 100 pounds per cycle.

Watching freshly cleaned garments emerge pristine, odor-free, and intact—without a single drop of water—he couldn’t believe his eyes.

“No detergent? No water? And they last longer?” he asked.

“Yes,” Mr. Thompson smiled. “It’s the future.”

Bringing the Future to India

Back in Patna, Mr. Dhobhi couldn’t stop thinking about what he had seen. If a water-abundant country like the U.S. had entrepreneurs successfully using such machines for the hospitality and apparel industries, then in water-stressed India, the potential was enormous. Could India adopt such a system? Could he bring a waterless laundry revolution to a country where millions lacked access to clean water?

Determined, he researched global alternatives:

1. 80Wash (India): Used supersaturated steam for water-efficient cleaning, showing promise for small businesses and quick-turnaround laundry needs.

2. Xeros Technology (UK): Utilized polymer beads for stain removal, offering an innovative but maintenance-intensive solution.

3. China’s Patent (CN105063960B):Focused on static dust removal but was still in early-stage development.

Each of these technologies had unique benefits, but after thorough evaluation, Mr. Dhobhi chose liquid CO₂. Its commercial success in the U.S. and proven ability to meet business demands made it the best fit for India’s commercial laundry sector.

Building India’s First Liquid CO₂ Washer-Dryer

However, importing Tersus machines was expensive. So, he partnered with one of India’s top engineering colleges to develop a homegrown alternative.

After two years of research and development, his team built India’s first liquid CO₂ washing machine—compact, energy-efficient, and affordable. He launched his first waterless laundromat in a high-rise residential complex in Patna, serving 100 households across three apartment buildings.

The impact was immediate and revolutionary:

1. Water tanker dependency dropped—residents no longer needed expensive water deliveries. Even those who didn’t depend on tankers saw their water utility expenses decrease.

2. Labor costs decreased—households previously paying for hand-washing saved thousands per year.

3. Convenience improved – his laundromat offered pick-up and drop-off services, a game-changer for busy families.

4. Clothes lasted longer—thanks to liquid CO₂’s gentle cleaning process, reducing fiber damage.

5. Energy consumption reduced—as liquid CO₂ cleaned and dried clothes in one machine versus a traditional water based system.

A Contract with India’s Defense Forces

The success of his first laundromat caught the attention of the Indian defense forces. The army, operating in water-scarce regions like Ladakh and Rajasthan, saw the potential of waterless laundry for field-based uniforms.

After successful trials, Mr. Dhobhi secured a massive contract to install liquid CO₂ laundromats in military bases nationwide.

Mr. Dhobhi Waterless Laundromat: A National Franchise

With proof of concept established, he launched Mr. Dhobhi Waterless Laundromat as a nationwide franchise model. He trained entrepreneurs across India to set up their own laundromats, offering them a turnkey business solution.

In just five years, he expanded to:

1. Fifteen major cities in India.

2. Service contracts with hotels, hospitals, and large corporate offices.

3. A research center in Ranchi to explore liquid CO₂ cleaning for restaurateurs, given its non-toxic and biodegradable properties.

From Rags to Riches: A New Industry is Born

From a humble washerman in Patna to the founder of India’s first waterless laundry empire, Mr. Dhobhi’s journey was extraordinary. But his greatest achievement wasn’t just financial success—it was job creation on an unprecedented scale.

Economists estimated that if India fully adopted waterless laundry, it would:

1. Save approximately 10 billion cubic meters of water annually.

2. Generate employment for millions, including women and both skilled and unskilled workers.

The industry required a diverse workforce, including:

1. Machine operators managing daily operations.

2. Technicians maintaining advanced CO₂ systems.

3. Logistics personnel handling pick-up and delivery services.

4. Cashiers managing billing and customer service.

A Waterless Future for India

Thanks to Mr. Dhobhi’s vision, waterless laundromats were no longer just a futuristic concept—they were a reality transforming India’s urban and rural landscape. His story was proof that innovation, determination, and sustainability could go hand in hand.

Standing in his flagship laundromat in Mumbai, now a multi-millionaire, he watched as a machine cleaned another batch of clothes with zero water, zero waste, and a non-toxic, biodegradable residue.

Smiling, he said, “Water is too precious to waste. We’ve just begun.”