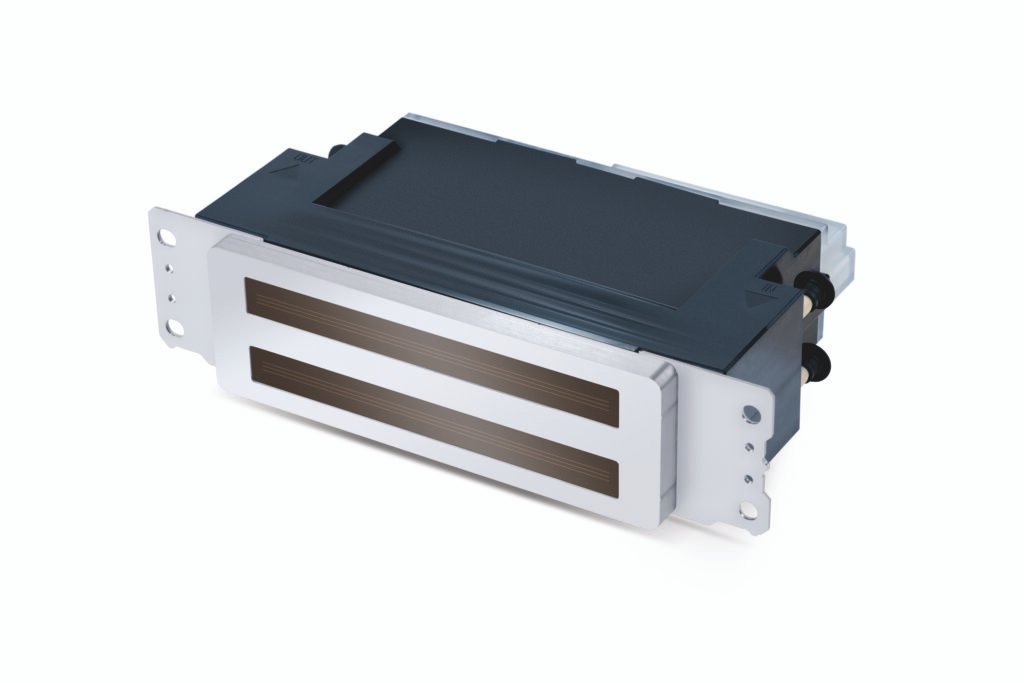

Seiko Instruments’ printhead division is poised to make a significant impact at DRUPA with the unveiling of its highly anticipated 600 dpi printhead – the ACROBAT – the RCE2560.

The excitement surrounding the RCE2560 stems from its groundbreaking combination of 600 dpi resolution, true recirculation, isolated channel technology, and integrated next-generation waveform controllers. This amalgamation of cutting-edge features ensures unparalleled printing performance and efficiency. With 2560 strategically distributed nozzles across four rows over a printing width of 108.3 mm, the RCE2560 delivers exceptional printing performance within a compact footprint. The recirculation system facilitates a uniquely high flow rate directly behind the nozzles, resulting in superior print quality and consistency.

One of the key highlights of the RCE2560 is its versatility, offering multiple grey levels with a drop volume range from 9 to 20 pl along with the possibility to accommodate various fluid types, including aqueous, solvent-, oil-, or UV-based inks. After undergoing extensive long-term testing under real conditions, equipped with the latest generation of waveforms, the RCE2560 is ready to conquer new markets with confidence.

Visitors to People & Technology’s booth C30 in Hall 5 will have the exclusive opportunity to witness the RCE2560 in action. Tailored for the textile and corrugated cardboard markets, the RCE2560 promises to captivate audiences with its performance.

Seiko Instruments aims to expand its reach beyond traditional markets like ceramics, coding & marking, and packaging, leveraging the RCE2560 to explore new opportunities. Collaborating with innovative partners, Seiko Instruments is committed to paving the way for sustainable solutions in diverse industries.

In addition, People&Technology will also demonstrate their complete fleet of machines such as the variants of the INKTESTER, the BACKTRACK, the SMART CLEANJECTOR and a plethora of other machines. All these machines are also equipped with the different models of the real recirculation printhead, which Seiko Instruments brought into the market. We are talking about the RC1536. Established in the market for almost 10 years now, it has been constantly improved and fine-tuned to the ever-changing challenges of the markets. Be it for the compatibility with water-based inks or the introduction of the stainless-steel nozzle plate to perform in challenging environmental conditions and much more.

Seiko Instruments prefers to show its portfolio of products for a wide range of industrial applications, live instead of just a datasheet. Let’s talk about how a head really works, in front of a head, seeing it work live. PowerPoint supports everything; however, reality is much more demanding.

We dare, just because we totally trust our heads. Always live, always in the latest application examples from renowned integrators, where various inkjet components are already optimally coordinated with one another.

At the ESMA Pavilion in Hall 3 stand no. 81-5, the company K-Flow Consulting GmbH shows what they have set up in collaboration with the machine manufacturer IdeeGO GmbH. A robotic arm, the LabelSaver from OPM Europe BV, positions a water bottle for direct-to-shape printing under a print bar equipped with two RC1536 printheads, one for the use of UV and one for aqueous ink.