amazed by the TC 30i. Owner of Mayfil Tekstil Burak Ateş, Regional Service Manager Trützschler Temasa Osman Kutlutürk, and Factory Manager Mayfil Tekstil Önder Bilir are seen from left to right.

In January 2024, Trützschler’s next-generation carding machine hit the market, and yarn makers all over the world are starting to believe in it. Excellent results have been obtained by the devices in testing conducted with consumers in Turkey and other countries. It succeeded up to 40% increased productivity with up to an 18% decrease in energy usage.

Reduced energy use and increased productivit

One of the top manufacturers of textured yarn in the Turkish textile sector is Mayfil Tekstil. The company’s main office is in Nilüfer, Burga. Since its founding in 2005, it has expanded quickly by putting the needs of its clients first.

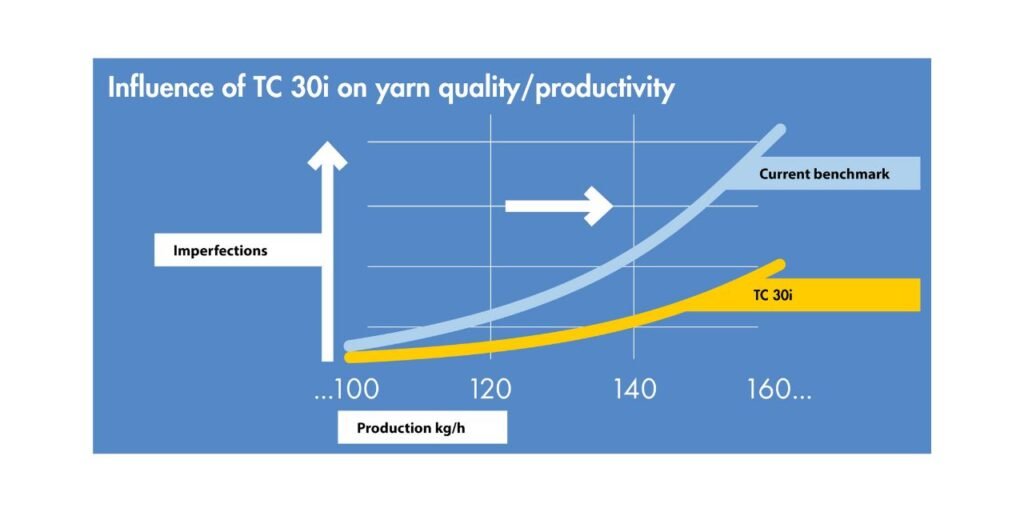

Mayfil made an investment in a cutting-edge vortex airjet spinning plant in 2022, with the capacity to generate up to 35 tons daily. In addition, the business was eager to examine the TC 30i for synthetic fibers in detail in order to determine whether it might help Mayfil achieve its aspirational expansion goals. Mayfil Tekstil tested the TC 30i in February of 2024. The carding machine of the following generation generated 140 kg/h viscose, which is more than

40% more than Mayfil’s 95 kg/h production rate using the current benchmark. Additionally, the new carding machine reduced power use by 18%. These findings have led Mayfil to buy more TC 30i cards.

Results validated

Inegöl Bursa-based Göl Iplik \eremet Tekstil Sanayi ve Ticaret A.S. runs three facilities that produce a range of high-quality goods, with blended yarns being their area of expertise. The secret of Göl Iplik’s success is its commitment to investing in cutting-edge machinery and innovative new items that broaden its line of business. for nearly forty years. In early 2024, Göl Iplik tested the TC 30i for synthetic fibers as well. Through thorough viscose experiments, this Trützschler client examined the TC 30i in great detail. The TC 30i used 15% less electricity while achieving a 40% greater output rate with the same level of quality. Göl Iplik now plans to incorporate the TC 30i into its next investment plan.

promising comments

Although the TC 30i is still relatively new to the textile industry, spinning enterprises all over the world are quickly becoming aware of its many useful features and functionalities. It makes a strong case for improving quality, productivity, and resource efficiency. More and more businesses worldwide have placed our TC 30i purchase. We are pleased to have won over additional clients globally.

Advantages of the TC-30i:

1)Top grade available from any raw material: High levels of output and yarn quality are made possible by the T-GO automated carding gap optimizer, the longest carding length available, and 35% more active flats.

2) Operator-independent performance: The automated, real-time adjustment of the carding gap with T-GO provides consistent results without the need for manual operators.

3) Value-adding waste management: A creative waste suction system gathers and sorts various waste materials. Over 50% of card trash may be recycled or profitably sold to other parties.

The experts in blended yarn at Göl Iplik Şeremet Tekstil Sanayi ve Ticaret A.. are Erdinç Şeremet, the deputy chairman of the board of directors, and Mümin Tarlak, the deputy general manager, in order from left to right.

Diagram: As production volume grows, the TC 30i produces noticeably less yarn defects while making man-made fibers.

Concerning Trützschler:

Based in Münchengladbach, Germany, the Trützschler Group SE is a manufacturer of textile machinery. Three business units comprise the company: Card Clothing, Nonwovens, and Spinning. Trützschler equipment, installations, and spare parts are created and manufactured in nine places all across the world. These include locations in China (Jiaxing and Shanghai), India (Ahmedabad), the United States (Charlotte), Brazil (Curitiba), and Germany (Dülmen, Egelsbach, Mönchengladbach, Neubulach). Customers may be found close by in strategic areas for the textile processing sector thanks to service providers in Turkey, Mexico, Uzbekistan, Vietnam, and Pakistan, as well as service centers in Bangladesh, Indonesia, and Pakistan. For further details, go to www.truetzschler.com.