Aditya Shankar Ghosh & Rishav Singh, Assistant Professor, Dream Institute of Technology, Kolkata

Pradip Kumar Choudhury, Former Principal Scientist & Former Technical Advisor, National Jute Board, Ministry of Textiles, GoI, Kolkata.

Abstract

Jute Geotextile (JGT) emerges as a promising natural alternative to synthetic geotextiles, demonstrating effectiveness in addressing various soil-related civil engineering challenges. Falling under the technical textile class of GEOTECH, JGT facilitates soil behavior enhancement and functions as a change agent, gaining acceptance among end-users due to its eco-compatibility, technical features, and competitive pricing. Research advancements continuously refine JGT’s fabric properties, with proven technology validated by laboratory studies and field applications nationwide. Contrary to conventional belief, JGT’s biodegradability is not a technical impediment, as its initial durability adequately supports soil consolidation processes. Moreover, JGT’s cost competitiveness against synthetic counterparts offers significant savings in construction projects, particularly evident in road construction and river bank protection. Highlighted advantages of JGT include its high tensile modulus, yield strength, and adaptability to mold surfaces. It effectively controls surface erosion, offers easy customization, and integrates with soil during biodegradation. Standardization through published guidelines ensures its seamless integration into various civil engineering applications, as evidenced by over 205 successful field trials across 22 states in India. Environmental benefits further underscore JGT’s appeal, with carbon footprint reduction and CO2 absorption enhancing its appeal for sustainable construction practices. Leveraging jute’s socioeconomic significance, JGT contributes to oxygen production, soil fertility improvement, and employment generation in the agricultural sector. While challenges persist, including market competition and technological advancements, the future of JGT remains promising. Its pivotal role in sustainable engineering solutions, coupled with governmental support and industry innovation, positions JGT as a vital component in addressing geotechnical challenges while preserving environmental equilibrium and socioeconomic stability.

Introduction

A natural alternative to synthetic geotextiles is the Jute Geotextile (JGT) [8]. It falls under the GEOTECH category’s technical textile class [8]. It handles a variety of soil-related civil engineering issues. It enhances the way soil behaves and functions as a change agent [3].The product is gaining acceptability among end-users in view of its effectiveness, eco-compatibility, appropriate techno-physical features and price-competitiveness. Research and studies on jute have helped continuous improvement in fabric features.

Technology

Technology for use of JGT stands proven on the strength of laboratory studies and substantive field applications. It has been and is being used all over the country for erosion control, river/ canal bank protection, in road construction, for prevention of railway track subsidence and slope protection. The technology of application is similar to the one for synthetic geotextiles. The three functions of geotextiles like separation, filtration and drainage act concurrently to build up effective stress within the soil. The widespread belief that a geotextile’s extended endurance is crucial for developing effective stress[7] stands contested by findings of the lab scale studies and field scale applications with JGT which have conclusively shown that in no case durability of more than two years is normally needed for consolidation of soil to an optimal level. The period over which soil consolidates in the presence of geotextiles for most applications does not warrant the durability of

Laying of Jute Geotextile on Eroded River Bank

the geotextiles beyond the initial period of consolidation during which soil consolidation is optimized. Consequently, JGT’s biodegradability is not a technical drawback [8].In view of the global concern for preservation of environment, JGT with its strong eco-concordance becomes a natural choice for policy makers and engineers alike for addressing various geotechnical problems in civil engineering.

Benefits of Jute Geo-Textile

There are many advantages of JGT as follows:

- High tensile modulus.

- High yield strength.

- High roughness co-efficient.

- Of all geotextiles- synthetics and naturals it has the best capacity to adapt to the mold surface

- It effects better on-land storage needed for surficial soil erosion control.

- The thickness of the open weave JGT aids in controlling surface soil erosion by slowing down overland flow and ensnaring loose soil particles [4].

- Easy availability.

- Could be customized to meet end users’ demands

- Reasonably priced as compared to synthetic geotextiles.

- Its properties improve and it becomes miscible with soil during biodegradation.

- Excellent spinnable and weavable fiber.

Price Competitiveness of JGT

One of the advantages of using JGT is its price competiveness against all other types of geotextiles available in India. JGT is competitively priced compared to similar synthetic geotextiles (SGT) in India. Cost of coir geotextiles is also much above than that of JGT. Use of JGT results in significant economy in construction of roads and river bank protection.

When comparing the traditional cost of employing JGT with the current Schedule of Rates of PW (Roads) and Irrigation & Waterways Department of the Government of West Bengal, there may be a direct saving of roughly 10% to 12%. When JGT completely substitutes the granular filter that is often used in river bank protection projects, cost reductions can reach 20% of the standard method [6].

Bio-Degradability of JGT- Is It a Technical Different?

End users frequently inquire about JGT’s low durability because they fear that the material’s biodegradation could jeopardize the stability of any construction made possible by using JGT. This idea is based on a naive understanding of the process underlying the interaction between soil and geotextile, not on reality.

By simultaneously performing the functions of separation, filtration, and drainage, all geotextiles serve as change agents for the soil they are placed on and enhance its behavior. Consolidating the soil is one of the three roles made possible by JGT’s high starting strength. Incidentally, consolidation is a long process that involves gradually lowering the pore water content of a soil body over time [8].Appropriate geotextile quickens the process of consolidation and optimizes it within a couple of season cycles. If JGT can be made to retain its initial essential features like strength and porometry up to acceptable limits, then it satisfies all technical reasons to be used in place of its synthetic counterpart. As a result, contrary to popular belief, the biodegradation of JGT after a year is not a technical barrier.

Comparison with Synthetic Geotextiles.

SGT experiences 10%-12% higher extension-at-break compared to JGT. Lower extension-at-break helps induce larger membrane effect and resultant higher CBR in road subgrade. Moreover environmentally and price-wise the JGT has an edge over the SGT.

Application Areas of JGT

JGT has applications that are advantageous in the following areas:

- Protection of slopes in earthen embankments, hill slopes, dumps and heaps of granular materials like fly ash.

- Erosion control in river banks, waterways and canals.

- Road Construction.

- Control of railway track settlement.

- Concealed drain construction in hill roads.

- Soft soil consolidation by pre-fabricated vertical jute drains.

- Watershed management and prevention of denudation of arid and semiarid lands.

In India, the potential of JGT for geoenvironmental applications is still untapped. Within urban conglomerates, one such area is the solid waste cover using the non-woven kind of JGT. Because JGT is biodegradable, it has an advantage over its synthetic counterpart in geoenvironmental applications [3].

JGT makes bioengineering procedures easier. The World Bank now recommends using bioengineering methods to treat degraded soil. In these situations, JGT increases soil permeability and mulches the soil, hastening the growth of vegetation [9].

Important Projects with JGT

- PMGSY Pilot Project with JGT

With the help of the Ministries of Rural Development and Textiles, a JGT pilot project was launched in 2006 on nine highways (a total length of 40.34 km) in five states: Assam, Chhattisgarh, Madhya Pradesh, Orissa, and West Bengal. The DPRs were created and Central Road Research Institute tracked the performance of these five routes. The state governments in question carried out the project. The JGT-applied roads’ satisfactory performance report, which was provided by CRRI, was sent to NRRDA, which is the PMGSY/Bharat Nirman nodal agency responsible for managing rural road construction. The Ministry of Rural Development encourages the use of JGT as an inventive and practical engineering material for rural road construction under PMGSY.

b.International Project on JGT

As many as 26 field trials with JGT have been completed for implementation the majority of which has been completed.

Standardization of JGT in India

- Published Standards and Normative References

- Bureau of Indian Standards

- IS:14986-2001Guidelines for application of Jute Geo-textiles for rain water erosion control in road and railway embankments and hill slopes.

- IS:14715-2000Woven jute geotextiles- Specifications..

- Ministry of Railways

- Guidelines for application of jute geotextiles in railway embankments and hill slopes. (No RDSO/2007/GE:G-008-February 2007).

- Indian Roads Congress

- IRC:SP:126-2019 Guidelines for the design and construction of low volume rural roads using jute geotextiles.

- IRC:SP:59-2019 Guidelines for use of geosynthetics in road pavement and associated works.

Field Applications with JGT

Efficacy of JGT is well established through more than 205 trial application conducted in different geographic locations at 22 States. Out of the 205 field applications 28% applications were in Erosion Control and Hill Slope Stabilization, 32% in road construction, 25% in river bank protection, 4% in control of railway track settlement and 11% in Agri-Horticulture and Forestry. The State Rural Road Development Agency (SRRDA) in India has received guidelines from the National Rural Road Development Agency (NRRDA) about the use of JGT for research and development. The guidelines mandate that 15% of the project’s overall length be used for this purpose [1].

Environmental Benefits of JGT JGT has an unassailable environmental edge over its man-made counterpart. The present global emphasis is on carbon foot print reduction in construction. Study conducted by PWC has shown the effectiveness of JGT in carbon sequestration, CO2absorption and O2 release. It is for this reason, adoption of bio-engineering measures is being advocated for control of surficial soil-related damages and distresses.

In light of jute’s eco-concordance and socioeconomic significance, the following points are pertinent:

- One hectare of jute may release around 11 MT of oxygen and absorb approximately 15 MT of CO2 from the environment in the course of a 100-day growth season. Research indicates that the rate at which jute absorbs CO2 is significantly higher than that of trees

- Aside from various domestic use, jute sticks are primarily used as fuel. Jute stick yield is 2.5 times the weight of fiber. Every year, 5.06 MT of bamboo and forest wood are saved by jute sticks in Bangladesh and India, contributing to the preservation of the natural equilibrium [2].

- Jute leaves that are left in the field make excellent manures and improve the soil’s fertility.

- A significant amount of direct employment is generated by jute farming for farmers, industrial workers, and employees of ancillary businesses [4].

The Table No. 1 portrays a comparative study of jute and polypropylene in respect to the waste generation, energy consumption and CO2emission.

| Parameter | Jute | PP | Ratio (PP/ Jute) |

| Waste produced (tons of Waste/ ton of product) | 0.9 | 5.5 | 6.1 |

| Water Consumption per ton of product (m3) | 54-81 | 1.3 | 0.016-0.02 |

| Energy Consumption per ton of product (Giga joules/ ton) | 5.4-14.35 | 84.3 | 5.9-15.6 |

| CO2 emission (tons of CO2/ ton of product) | -1.2-0 | 3.7-7.5 |

JGT poses no environmental threat. Being biodegradable JGT ultimately coalesces with the soil on which it is laid, exerts a mulching effect on soil, creates a congenial micro-climate, adds nutrients to it on bio degradation and quicker growth of vegetation. Engineers have recently been aware of the issue of greenhouse gas emissions in the production of building materials, which has prompted a thorough investigation and search for novel, environmentally friendly solutions. A gradual transition from conventional materials to new, less polluting building elements has occurred as a result of concerns about environmental contamination caused by the unchecked use of fossil fuel byproducts and stone mining in the construction industry.

Jute plays a crucial role in the national economy sustaining 4 million agricultural workers who cultivate jute and another almost half a million labour work force engaged in production of jute goods. It is important to protect this sector, which is a source of livelihood to many, but it is even more necessary to protect the fibre in view of the long-term implications for the environment. The government of India had enacted the jute Packaging Materials Act. 1987, which provides for compulsory use of jute in packing of certain commodities. This law was brought to protect the sector and it has achieved the purpose over the last two decades. The state agencies use jute bags for storage of food grains and sugar mills use bags for packing sugar. However, the availability of cheaper substitutes, improvements in technology of bulk storage and containerized transportation are challenges, which may ultimately reduce the demand for jute bags in future. Jute sector has started looking beyond sacks. The futute of jute will therefore depend largely on JGT.

Table 2: Comparative properties of woven JGT and SGT with important features

| Requirements | Property/ Test Methods | Units | Elongation at Failure Strain < 50% | |

| SGT | JGT | |||

| Highway requirements | Grab Breaking load and Elongation (ASTM D 4632) | N | 1100 | 1200 |

| Trapezoid Tearing Strength (ASTM D 4533) | N | 400 | 500 | |

| Index Puncture Resistance (ASTM D 4833) | N | 400 | 450 | |

| Diaphragm Bursting Strength (ASTM D 3786) | kPa | 2700 | 3200 | |

| Average Opening Size (ASTM D 4751) | µm | Any aperture as per average grain size distribution | ||

Table 3: Properties of Jute Fibre

| Properties | Jute |

| Specific Gravity | 1.48 |

| Tenacity, g/d | 3 to 5 |

| Breaking Elongation, (%) | 0.8 to 2.0 |

| Elastic Recovery, (%) | 75 to 85 |

| Moisture Regain (%) | 12.5 to 13.8 |

| Effect of Heat | No melting up to 356 F. The weight and tenacity remains intact. 559 F is the melting point of the Hemi cellulose [1]. |

| Effect of Acid/ Alkalies | Strong resistance to weak acids, but weakens in concentrated acids and is impacted by heated alkalis[8]. |

| Resistance to Mildew again, sunlight and abrasion | Comparatively low resistance (>75%) to mildew attack in damp environments [1]. Have a high coefficient of rugosity. Resistant to UV light. |

Table 4: Specifications of Jute Geotextiles

| Construction | Use of Double Warp Plain Weave on Rural Roads | Application of Double Warp Plain Weave in River Bank | Jute geotextiles with an open weave for stabilizing slopes: Soil Saver | ||

| Width (cm) | ≥200 cm | ≥200 cm | ≥122 cm | ||

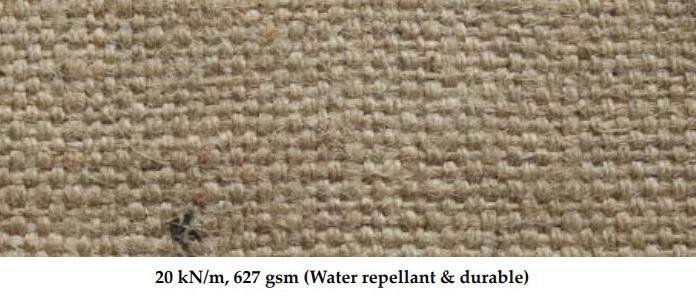

| Weight (gsm) at 20% MR | 730 (±5%) (Untreated) | 625 (±5%) (should be given the appropriate additional treatment) | 500 (±10%) | 600 (±10%) | 700 (±10%) |

| Ends x Picks/ dm | ≥95 x 38 | ≥86 x 33 | ≥6.45 x 4.45 | ≥7.9 x 6.9 | ≥7.9 x 7.9 |

| Thickness (mm) | 1.86 (±10%) | 1.71(±10%) | 4.55 (±10%) | 5.30(±10%) | 5.49 (±10%) |

| Wide width Tensile strength (kN/m) | ≥24.9 x 24.9 | ≥19.5 x 19.5 | ≥6.5 x 5.9 | ≥11.9 x 5.9 | ≥13.9 x 6.8 |

| Elongation at break (%) MD x CD | ≥11.9 x 11.9 | ≥11.9 x 11.9 | ≥13.9 x 13.9 | ≥13.9 x 13.9 | ≥13.9 x 13.9 |

| Index Puncture Resistance (kN) | 0.489 (±10%) | 0.409 (±10%) | x | x | x |

| Burst Strength (KPa) | 3489 (±10%) | 3098 (±10%) | x | x | x |

| Permittivity at 100 mm constant head (/s) | 0.348 (±10%) | 0.348 (±10%) | x | x | x |

| A.O.S (Micron) O95 | 145-395 | 145-395 | x | x | x |

| Open Area (%) | x | x | 454-65 | 45-65 | 40-45 |

| Water Holding Capacity (%) on dry weight | x | x | 440-495 | 445-495 | 550-600 |

Conclusion

There are numerous possible uses for jute geotextile, in civil construction projects. Jute fabrics’ engineering qualities make them appropriate for separation, strengthening, drainage, and filtration tasks as well as for resolving geotechnical issues with weak soil. Jute geotextiles can be made in woven or nonwoven formulations to meet specific needs, or they can be made in any of the several composite forms that can be made with different natural or synthetic combinations. Applications employing jute/jute composite geotextiles for slope and bank protection, as well as prefabricated vertical and horizontal drainage, have shown to be dependable successes. It is economically viable, ecologically friendly, and has technically possible applications.

Reference

1. Board, N. J. (2016). Development and application of potentially important jute-geotextiles. New Delhi.

2. Choudhury, P. (2013). Application of jute geotextiles for construction of rural roads under PMGSY.

3. Ghosh, S. K. (2013). A Review on Jute Geotextile and its Geo-Technical Applications with respect to Environmental Concern. International Journal of Innovative Research in Science & Engineering .

4. Khastagir, T. S. (2012). PREPONDERANCE OF JUTE AS GEOTEXTILES. GEOSYNTHETICS ASIA 2012, 5th Asian Regional Conference on Geosynthetics 13 to 15 December 2012, (pp. 437-442). Bangkok, Thailand.

5. S.K. Ghosh, R. B. (2014). A review on jute geotextile-part 1. International Journal of Research in Engineering and Technology Volume: 03 Issue: 02 , 378-386.

6. Saha, R. (2018). Economical and environmental advantages of using jute geotextile in rural road, river bank protection and hill slope management. Kolkata: National Jute Board.

7. Sanyal, T. (2016). Jute Geotextiles and their Applications in Civil Engineering, Developments in Geotechnical Engineering. Springer Singapore.

8. Sanyal, T. (2016). Road construction with jute geotextiles.

9. Stathakopoulos, N. G. (2006). Bioengineering techniques for soil erosion protection and slope stabilization.